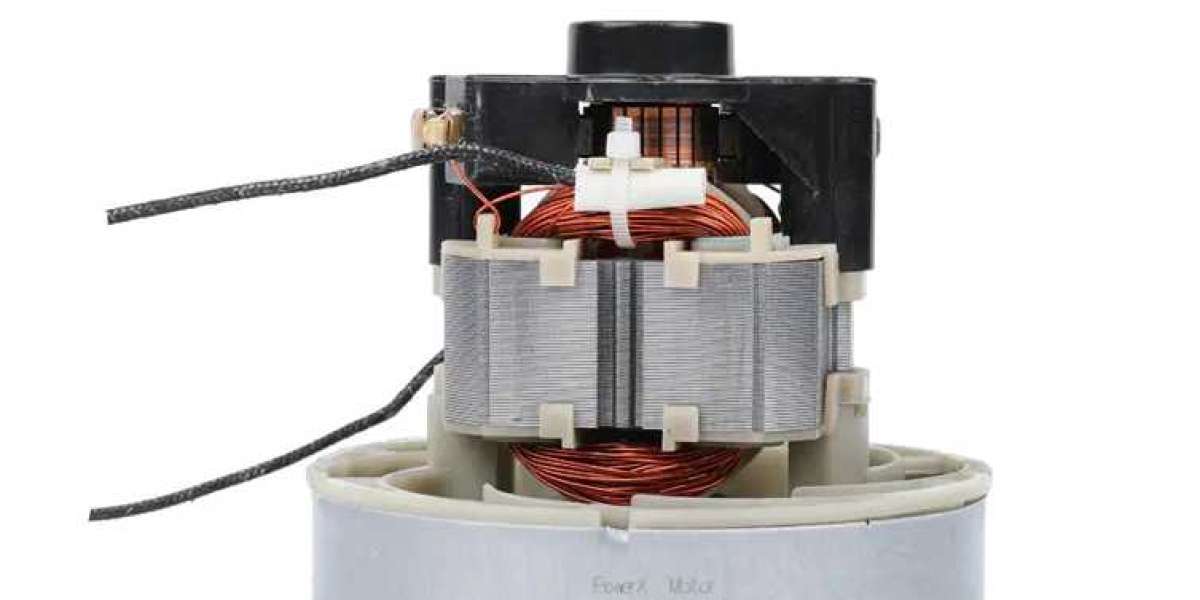

The production of shaded pole motors involves several steps, starting with the creation of the stator and rotor components. Laminated sheets of silicon steel are used to form the stator, which includes slots to hold the winding.

The shading coils, typically made from copper, are installed on a portion of each pole. These coils play a crucial role in generating the necessary rotating magnetic field.

The rotor, usually a squirrel-cage type, is assembled next, followed by mounting it within the stator. Additional components, such as bearings and end shields, are added to ensure smooth operation.

After assembly, the motor undergoes testing to verify its performance and reliability. This careful manufacturing process ensures that shaded pole motors meet the required standards for diverse applications.