In today's rapidly developing era, plastic products play an increasingly important role in our daily lives. From food packaging to industrial transportation, plastic products are the material of choice for many industries because they are lightweight, durable and cost-effective. Among them, plastic crate mold is a key link in the production of plastic products, and its precision is directly related to the quality and performance of the product. This article will explore in detail the high-precision efforts made by the plastic crate mold factory in producing milk box molds.

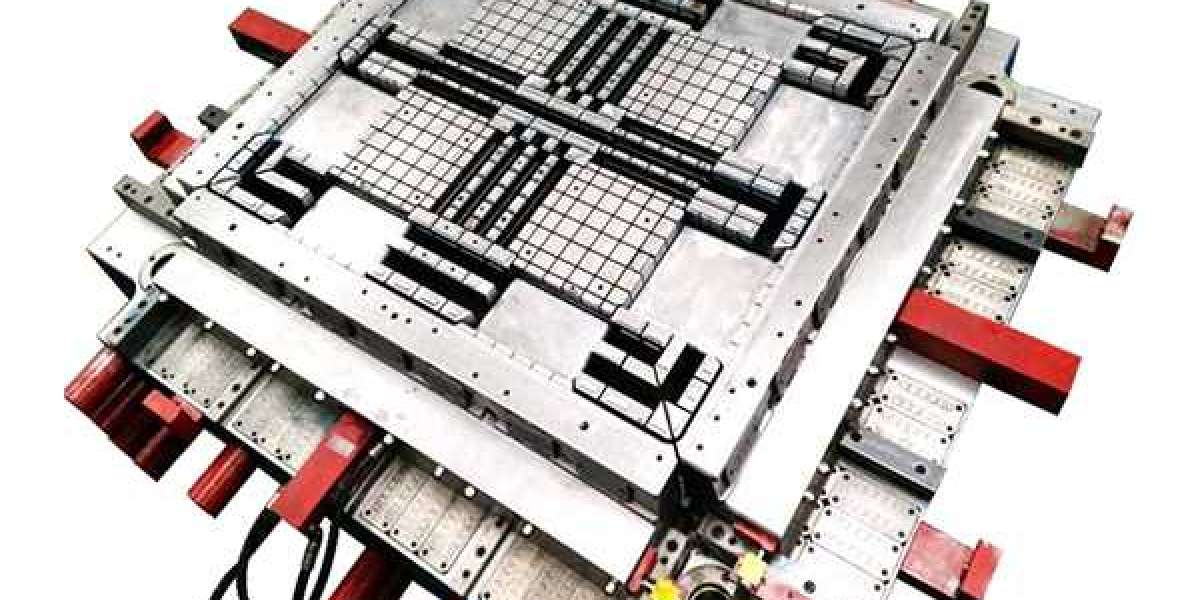

In the selection of mold materials, the plastic crate mold factory also spares no effort. The factory selected high-strength, high-wear-resistant steel as the raw material for the mold. These materials can not only withstand the long-term high-pressure injection molding process, but also ensure that the mold maintains shape stability and dimensional consistency during repeated use. In addition, the factory also performs a special hardening treatment on the mold surface to improve its durability and corrosion resistance.

In terms of mold debugging and optimization, the plastic crate mold factory also demonstrates its unremitting pursuit of high precision. The factory has an experienced technical team who are responsible for debugging the mold to ensure that the mold can achieve the outstanding performance in actual production. Through continuous optimization of molds, the factory is able to produce milk box molds that are more accurate and more in line with customer needs.