In the world of manufacturing, Tool Box Mold plays an essential role in the production of various types of toolboxes and accessories. These molds are specifically designed to ensure the accurate and efficient replication of intricate designs, allowing for the mass production of high-quality toolboxes and their components. Whether for automotive, aerospace, construction, or DIY applications, toolboxes are crucial for organizing and storing tools, and molds are the backbone of their production. Learn more about how these molds are made and used by visiting Tool Box Mold.

Design and Engineering of Tool Box Molds

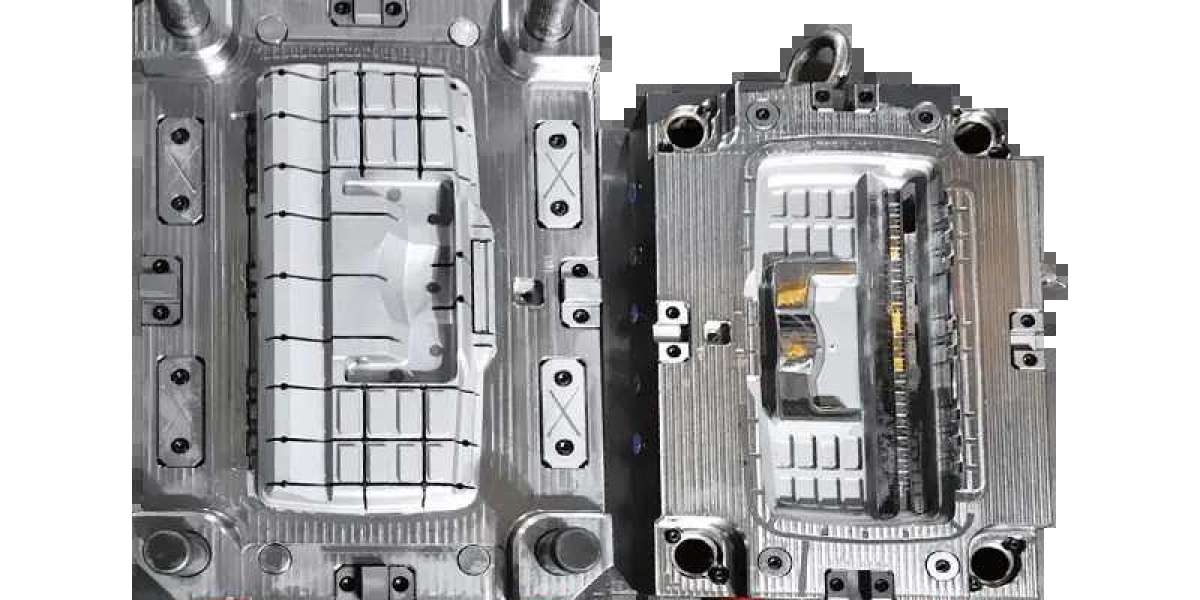

The process of designing and engineering Tool Box Molds involves careful consideration of the product’s specifications. Engineers utilize advanced CAD software to create precise mold designs that meet the functional requirements of toolboxes and accessories. During the design process, several factors are taken into account, such as material selection, mold cavity design, and cooling systems, which are all crucial for ensuring mold performance and longevity.

Selecting the right material is equally important. Molds are typically made from durable materials like tool steel or aluminum alloys, chosen for their wear resistance and thermal conductivity. The material choice is influenced by factors such as production volume, part complexity, and budget. Precision machining techniques like CNC milling and EDM are then used to manufacture the molds, ensuring high accuracy and repeatability in the production process.

To explore more about how these molds are designed and engineered, check out the detailed offerings at Tool Box Mold.